-

Product DescriptionCompany Info.

- Material:

- Metal

- Filter element form:

- Sintered filter

- Use:

- vacuum-pumping equipment

- Applicable scope:

- Air cleaner

- Applicable object:

- Air

- Types:

- High efficiency

- Specifications:

- 50*500

- Operating temperature:

- 300 ℃

- Maximum working pressure difference:

- 0.6 Mpa

- Filtration accuracy:

- 5 microns

- Inlet and outlet caliber:

- 60 mm

- Raw water pressure:

- 30 kg/cm2

- Filter area:

- 0.0188

- Model:

- YG-2022-0412

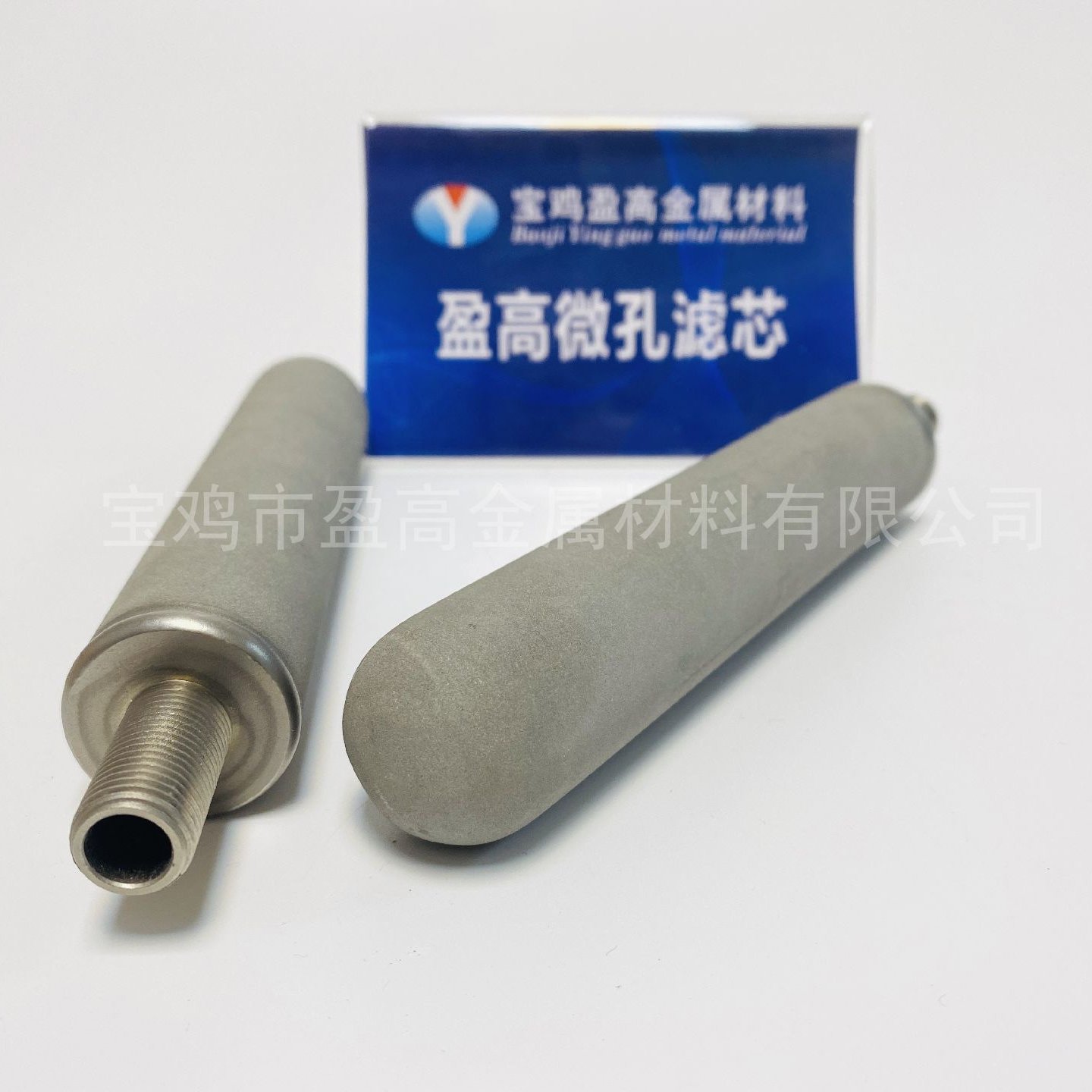

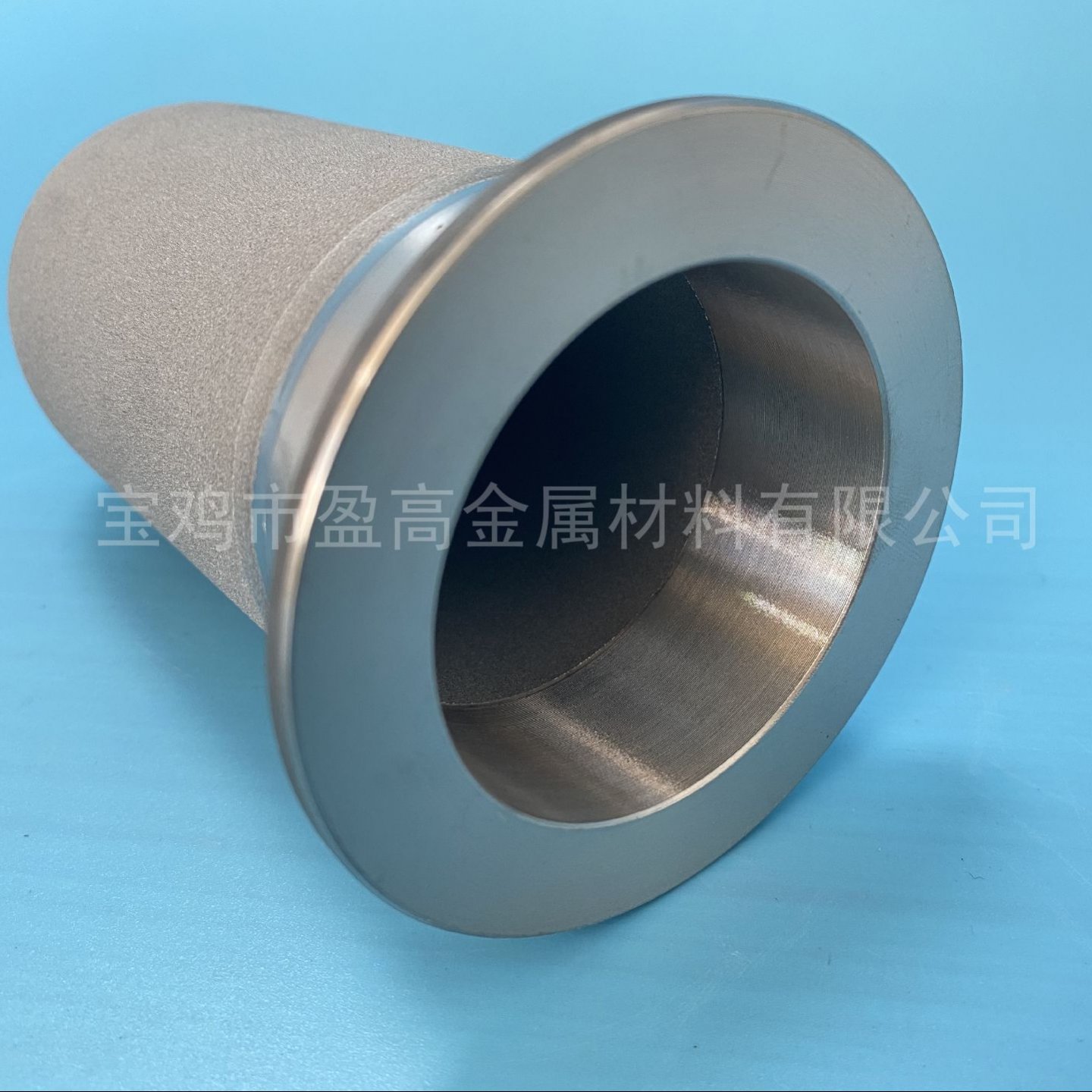

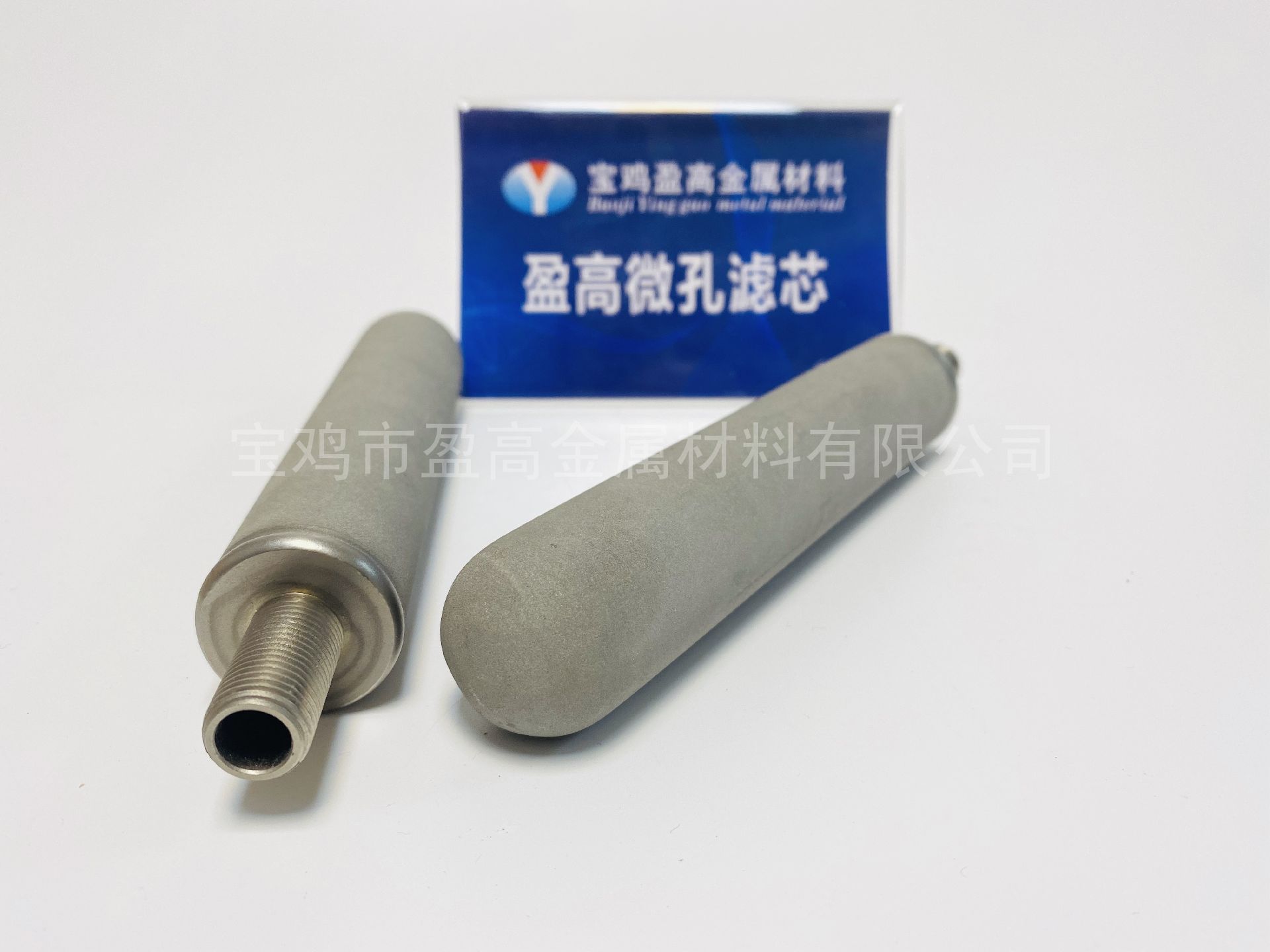

Silicon powder is used in the semiconductor industry. It is generally divided into polished surface and non-polished surface. The purpose is mainly to prevent silicon powder from adhering to the surface. The polished surface is smoother. Silicon powder is not easy to adhere. It can be easily blown back or cleaned. Immediately fall off, reduce cleaning pressure, and increase reuse rate. As shown in the figure below is the polished surface, the surface has no obvious particle feeling, the smooth surface, basically a mirror state, does not affect the normal filtration efficiency, dust is not easy to adhere, easy to blow back or do surface cleaning. The following picture shows the unpolished surface, which can obviously feel the difference of the surface. It is matte surface and rough to the touch. For silicon powder, it can also be blown back or cleaned, which can play a very good role. It is also a common treatment method for silicon powder filtration.

Product operation precautions:

1. It must be used vertically. Before installation with the shell, it is necessary to check whether each sealing ring is in place. It is strictly prohibited to leak and misplace each sealing ring. nbsp;

2, before normal use at least 3~5 minutes of low pressure start time, that is, the pressure gradually increased to 0.15~0.25Mpa, it is forbidden to instantaneous pressure. nbsp;

3. It is recommended to incorporate backwashing into the production process, that is, backwashing once every shift (8 hours) before work, the time of each backwashing is 10~20 minutes, the pressure of backwashing should be gradually increased to 0.25~0.3Mpa, and instantaneous pressurization is strictly prohibited. nbsp;

Product Details:

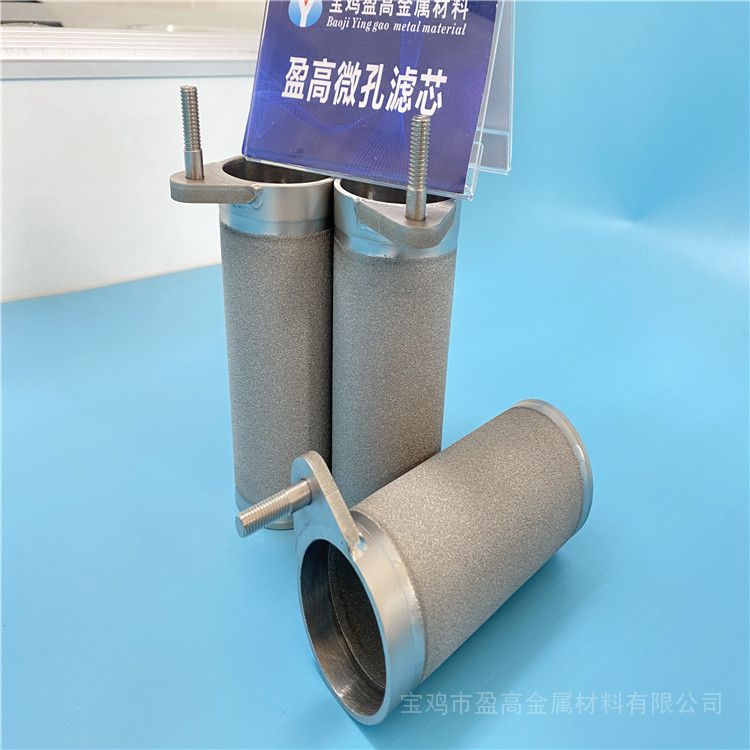

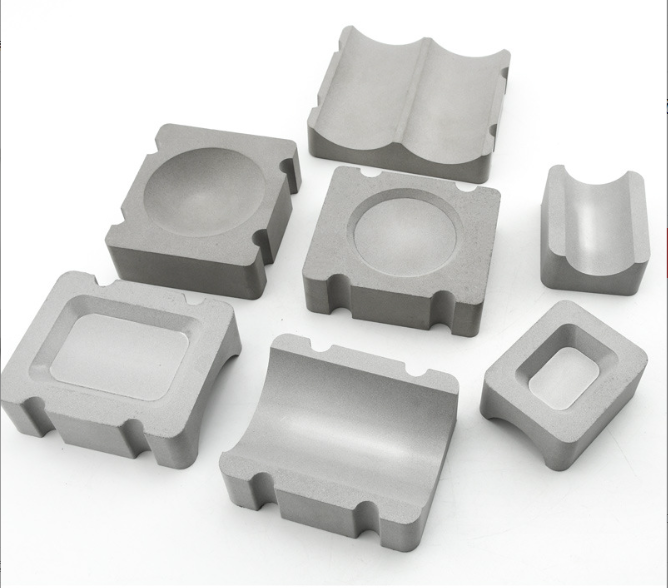

Powder sintering part, can be long or short, can be customized according to demand, can also be customized to produce abrasive tools, the general bottom seal, can be dense parts welding seal, can also be a powder molding, with an integrated filter effect. nbsp;

These porous metal membrane tubes are currently symmetrical in structure, and the pore size of the membrane is consistent in the entire fluid filtration direction (radial), which will greatly affect the performance of the membrane tube. Porous metal membrane pipe is different from ordinary metal pipe, it should have high strength, good corrosion resistance, but also have high filtration accuracy and large filtration flux. nbsp;

If the compact is sealed, the bottom does not have the effect of filtering. If the interface is connected, it can be connected to another part by welding to the powder sintering tube according to the common thread. Product form:

The product is in tubular form and consists of two parts, one part is powder sintered tube and the other part is dense interface, which are connected together by welding. Product Specificity:

At present, most of the silicon powder highly purified filtration anti-adhesion light mass titanium filter tubes are still in micron level, and the filtration accuracy is 2-50um, which is mainly used for fine filtration of liquids and gases. In practice, some people think that this kind of porous metal film is not a real film, but only porous metal. Product sintering process:

In this way, it is necessary to pass through multiple molding and sintering processes, because the price of metal powder required for the preparation of metal film is higher than that of ceramic powder, and its preparation cost is higher than that of ceramic film. If the existing multiple molding and sintering processes are adopted, the price of the metal film with multi-layer asymmetric structure prepared in this way will be expensive, which is higher than that of ceramic film and much higher than that of organic film, which will restrict the application and development of metal film.

If the metal film tube can be made by one-step molding, it is required that the metal film tube has a gradient structure, that is, the metal film with continuous pore diameter change in the radial direction has better performance than the metal film with multi-layer structure. The control layer or transition layer of multilayer asymmetric metal film is attached to the tube body of the previous layer of large pores. Because the diameter of powder particles is abrupt, the next layer of powder particles will inevitably block part of the large pores of the upper layer, which will reduce the permeability of the metal film. Product advantages:

It has three advantages: high mechanical strength, can be used under higher pressure, and will not cause deformation and damage of membrane components and membrane materials, so that in the membrane separation can be improved by increasing the pressure difference between the two sides of the membrane to improve the permeation rate, due to high strength in the operation is not easy to damage, can reduce the replacement of membrane components, in addition to excellent membrane carrier materials.

Second, it has good thermal conductivity. Since the material of the metal film is metal or alloy with good thermal conductivity, the metal film exhibits good thermal conductivity, good heat dissipation performance in high temperature (relative to organic film) application fields, and reduces thermal stress of the film assembly to improve the service life of the film assembly.

Third, its sealing performance is good. Membrane separation is carried out under a certain pressure, and the required membrane assembly has good sealing performance. The metal membrane material is a metal or alloy with good welding performance and has good sealing performance. Moreover, in the filtration process, the metal membrane has large adsorption capacity for dirt, good support, large filtration area, large temperature range, easy cleaning (chemical, mechanical or heating cleaning and backwashing can be carried out), long service life, and practical application value.

Titanium anode has been widely used in mechanical, electronic, chemical, atomic energy, medicine and health, biology and other fields.

At present, the multi-layer asymmetric structure is commonly used in the preparation of metal film tubes, that is, it usually includes a porous carrier (bottom layer) with a certain mechanical strength, about a few millimeters thick, which is the matrix of the whole film tube, and the mechanical strength of the film tube is guaranteed by it. A thin control membrane layer with a small pore size is arranged on the carrier, and the separation effect is mainly achieved by it. Between the carrier and the control film layer, there is also one or more intermediate transition layers, which is the multilayer asymmetric structure of the metal film.

Main performance:

1. Uniform pore size, stable pore shape and high separation efficiency.

2. High porosity, low filtration resistance and high permeability.

3, high temperature resistance, can be used normally below250℃.

4, good chemical stability, acid and alkali corrosion resistance (PH2-12), with oxidation resistance.

5, no particles fall off, do not make the stock solution form secondary pollution, in line with food hygiene and pharmaceuticalGMPrequirements.

6, good mechanical performance, low pressure difference, large flow rate, filter press can be filtered, simple operation.

7, strong antimicrobial ability, does not interact with microorganisms.

8, online regeneration, easy to clean, long service life (generally several times the membrane filter)

9, molding process is good, the overall length without welding can reach1000mm.

10. Non-magnetic and non-toxic, and has good compatibility with human tissues and blood. It is used in pharmaceutical industry and food.

Widely used in industrial and water treatment industries.mainly used

Petroleum, chemical industry, metallurgy, aviation, electronics, atomic energy, electric power, nuclear industry, pharmacy, environmental protection, refractory materials, fire fighting equipment and other fields. High strength, good toughness, suitable for high pressure environment

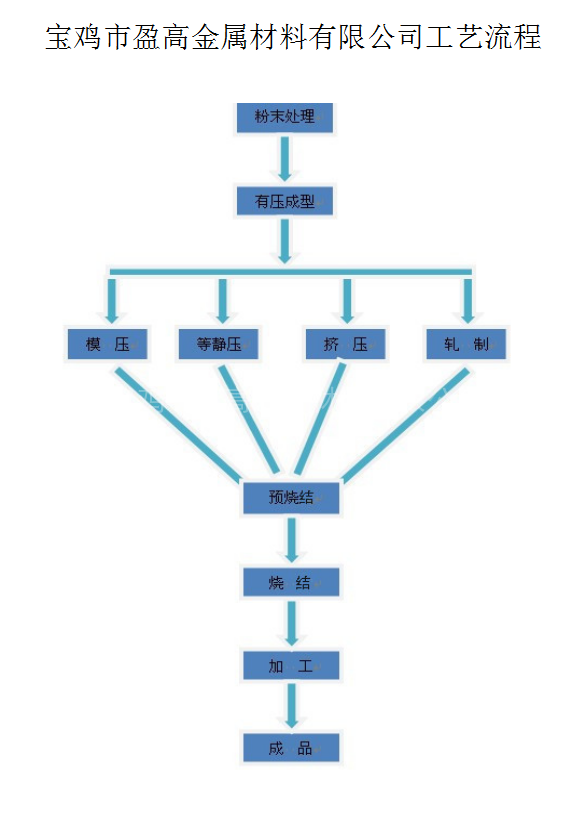

Manufacturing process: 1. hot forging, hot extrusion, hot rolling; 2. hot forging + turning (grinding), hot extrusion + turning (grinding), hot rolling + turning (grinding);

Supply state: 1. Hot working state (R); 2. Annealed state (M);

Diameter: 1. Forging titanium rodφ 26mm-200mm 2. Titanium extrusion rodφ 15mm-80mm 3. Titanium rolling rodφ 8mm-24mm

Executive standards: GB/T2965-2007, ASTM B348, GJB, AMSE and other national standards After-sales service:

For a company, after-sales service is very important, but also related to the vital interests of customers, Yinggao Metal adopts a single filing system, to customers for filing records, to customers for each order and use of the effect of return visit registration, regular communication and consultation, improve products and services, such as found due to product quality problems, time consultation.

Purchase Notes:

When purchasing metal film tubes, you need to inform specific specifications, such as diameter, length parameters, and accuracy parameters, which can be customized according to requirements.

If you need a dense interface, you need to inform the form of the interface, but also need to inform the precision parameters, the material is generally pure titanium, the brand is TA1, the purity is about 99.3% pure titanium.

Product essence Structural process: Product Description:

Different from the wire mesh pipe, powder sintering is a product that is pressed and molded by a mold. The essential structure is a powder-like structure, while the wire mesh is a filamentous internal structure. If the powder-like internal structure is relatively uniform, the porosity can reach 35%. In the fine filtration industry, the filtration efficiency can reach 98%. It is a very good microporous permeable filter material.

This silicon powder highly purified filter anti-adhesion light quality titanium filter tube product shape can be customized, can be added polishing process, can be adapted with your equipment different specifications different precision and different polishing degree, better solve the equipment for different requirements for blowback and cleaning.

Product suitability:

Silicon wafer raw material silicon powder purification metal powder sintering filter fine polishing is mainly suitable for polysilicon industry powder filtration and purification, to deal with fine particles, can be filtered, can be intercepted, can be blown back, polished surface can be blown back after cleaning, and then reused, replacement rate is low, cost saving, is a good alternative filter for polysilicon industry.

- Name(chinese)

- Name(English)

- Baoji Yinggao Metal Materials Co., Ltd

- China credit code

- Identity Verification

- Address

-

Shaanxi Baoji, China

- Nearby port

- Tianjin,Lianyungang,Shanghai,Shenzhen

Baoji Yinggao Metal Materials Co., Ltd. is located in the east area of Baoji High-tech Industrial Development Zone, known as the "China Titanium Valley", with convenient transportation and beautiful environment. Founded in 2011, the company has the latest and most advanced production equipment and rich production experience, and has provided related products and services to many large state-owned enterprises for a long time. The company mainly produces and sells various types of powder sintered filter components made from high-purity titanium powder as raw material (purity 99.60%) and sintered at high temperatures. The main products include: titanium rod filter elements, porous titanium plates, titanium electrode pads, nickel-based alloy powder sintered pipes, etc., stainless steel powder sintered filter pipes, metal aeration heads, and other products. The products are produced and implemented in strict accordance with national standards GB/T6887-2019, GB/T6886-2017, and GB/T5250-93. The products are widely used in petrochemical, hydrogen energy industry, vehicle and vessel heavy industry, pharmaceuticals, medical equipment, environmental protection and other fields. Our company is a modern private technology-based enterprise integrating scientific research, production and sales. It has passed the IOS9001 quality management system certification. The company takes the service purpose of "winning in service, being high in quality, making high in metals, and striving for excellence" and is dedicated to providing customers with high-quality and high-tech products. At the same time, our company has long been operating various specifications and models of titanium and titanium alloys, nickel and nickel alloy pipes, bars, plates, wires, as well as titanium-nickel standard parts, titanium-nickel products, etc. New and old users are welcome to visit and provide guidance. We are willing to join hands with friends from all walks of life to seek common development.- Name(chinese)

- Name(English)

- Baoji Yinggao Metal Materials Co., Ltd

- China credit code

- Identity Verification

- Address

-

Shaanxi Baoji, China

- Nearby port

- Tianjin,Lianyungang,Shanghai,Shenzhen

Baoji Yinggao Metal Materials Co., Ltd. is located in the east area of Baoji High-tech Industrial Development Zone, known as the "China Titanium Valley", with convenient transportation and beautiful environment. Founded in 2011, the company has the latest and most advanced production equipment and rich production experience, and has provided related products and services to many large state-owned enterprises for a long time. The company mainly produces and sells various types of powder sintered filter components made from high-purity titanium powder as raw material (purity 99.60%) and sintered at high temperatures. The main products include: titanium rod filter elements, porous titanium plates, titanium electrode pads, nickel-based alloy powder sintered pipes, etc., stainless steel powder sintered filter pipes, metal aeration heads, and other products. The products are produced and implemented in strict accordance with national standards GB/T6887-2019, GB/T6886-2017, and GB/T5250-93. The products are widely used in petrochemical, hydrogen energy industry, vehicle and vessel heavy industry, pharmaceuticals, medical equipment, environmental protection and other fields. Our company is a modern private technology-based enterprise integrating scientific research, production and sales. It has passed the IOS9001 quality management system certification. The company takes the service purpose of "winning in service, being high in quality, making high in metals, and striving for excellence" and is dedicated to providing customers with high-quality and high-tech products. At the same time, our company has long been operating various specifications and models of titanium and titanium alloys, nickel and nickel alloy pipes, bars, plates, wires, as well as titanium-nickel standard parts, titanium-nickel products, etc. New and old users are welcome to visit and provide guidance. We are willing to join hands with friends from all walks of life to seek common development.<> -

Send your message to this supplier*From:*To:

Miss. Crystal

*Message:

Miss. Crystal

*Message:Inquiry

Copyright © 2003 - 2025 Goepe.com All rights reserved.